Which mesh is right for your application?

Mesh selection is very important to the screen printing process. Let us help you select the correct mesh for your specific application. Explore the various lines of mesh that we offer below, access our digital catalog, or contact your Technical Sales Representative for more personalized help.

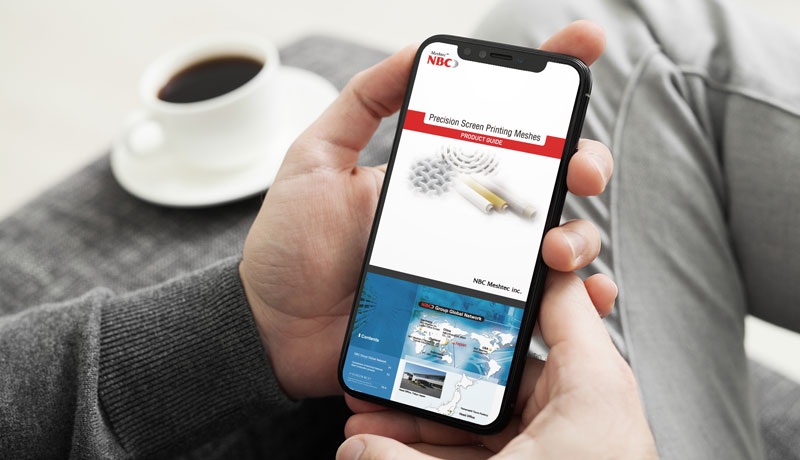

Access our mesh catalog

Learn more about our line of screen printing mesh products in the latest version of our digital catalog, available in two convenient formats:

Interactive Online Catalog

Downloadable PDF

We manufacture quality mesh

That’s what we’ve said from the beginning. But what do we mean by “quality?” Find out below.

Balance

Our strict quality control standards ensure that our mesh boasts an ideal warp/weft balance, contributing to a stronger, longer lasting screen. See how this can help save you time.

Durability

Our polyester mesh features threads with a high modulus rating. This makes for a whole range of meshes that are exceptionally durable. See how this can benefit your bottom line when it comes to high volume textile printing.

Precision

Our Alpha Series polyester mesh boasts incredible dimensional accuracy. See how it can help improve registration and repeatability in your process.

Strength

Our V-Screen Next mesh features threads with strength superior to stainless steel. See the difference that strength can make in your industrial or electronic printing process.

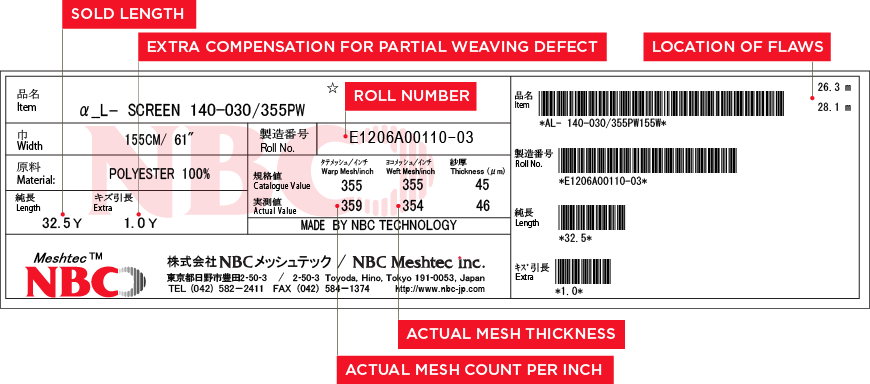

NBC Mesh Inspection Tag & Flaw Marking

Every roll of NBC synthetic screen printing mesh is supplied with an inspection tag. Thickness and mesh count are precisely controlled and documented on the tag along with the location of any flaws—critical information for setting and maintaining your production standards.

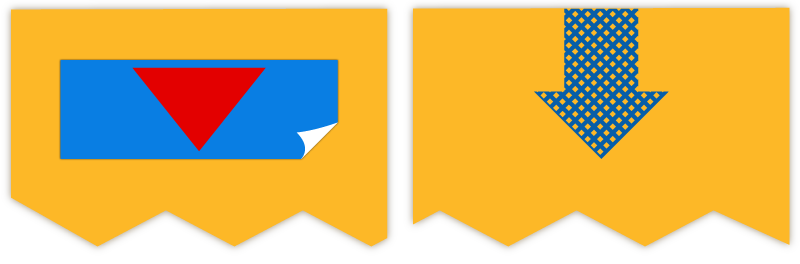

While flaws are kept to a minimum by careful quality control, any flaw found under our thorough visual inspection is clearly marked1 to prevent it being stretched into your image area. All such partial weaving defects will be indicated at the edge of the mesh using either the blue sticker or blue stamped ink arrow illustrated below. In addition, NBC compensates for flaws by adding one half yard of mesh to the end of the roll free of charge for each flaw found.2

The NBC mesh inspection tag and flaw markers are details easily overlooked. But they can go a long way toward keeping your presses running and saving time spent troubleshooting print errors.

Downloadable Resources

- In general, each marker will indicate a single flaw at that location. However, if several flaws occur within a single 4″ (10 cm) span, they will be represented by a single marker.[return]

- Flaw compensation policy applies only to NBC synthetic screen printing mesh. Metal mesh and industrial (e.g. filtering) mesh are not included. Additionally, any marked flaws within an 18″ (46 cm) space are considered to be one flaw and compensated with a ½ yard of material.[return]

NBC Mesh Tension Guide

Note: The tension measurements listed in this interactive table are intended only as a guideline.

Click here to download a printable copy of these mesh specifications

| MESH CODE | MESH COUNT /in (±3) | MESH COUNT /cm (±3) | THREAD DIAMETER µm | STANDARD TENSION N/cm | ADVANCED TENSION N/cm | EXPERT TENSION N/cm |

|---|---|---|---|---|---|---|

| 508 -024 PW | 508 | 200 | 24 | 16 | 19 | 25 |

| 508 -027 TW | 508 | 200 | 27 | 22 | 26 | 33 |

| 460 -027 PW | 460 | 180 | 27 | 18 | 21 | 27 |

| 420 -027 PW | 420 | 165 | 27 | 18 | 21 | 27 |

| 420 -030 PW | 420 | 165 | 30 | 24 | 28 | 36 |

| 380 -027 PW | 380 | 150 | 27 | 18 | 21 | 27 |

| 380 -030 PW | 380 | 150 | 30 | 22 | 26 | 33 |

| 380 -033 PW | 380 | 150 | 33 | 25 | 29 | 38 |

| 380 -035 TW | 380 | 150 | 35 | 30 | 35 | 45 |

| 355 -027 PW | 355 | 140 | 27 | 16 | 18 | 24 |

| 355 -030 PW | 355 | 140 | 30 | 21 | 25 | 32 |

| 355 -035 PW | 355 | 140 | 35 | 27 | 31 | 40 |

| 330 -027 PW | 330 | 130 | 27 | 15 | 17 | 22 |

| 330 -030 PW | 330 | 130 | 30 | 20 | 23 | 30 |

| 330 -035 PW | 330 | 130 | 35 | 26 | 30 | 38 |

| 315 -027 PW | 315 | 125 | 27 | 15 | 18 | 23 |

| 315 -030 PW | 315 | 125 | 30 | 18 | 21 | 28 |

| 305 -030 PW | 305 | 120 | 30 | 18 | 21 | 27 |

| 305 -033 PW | 305 | 120 | 33 | 21 | 25 | 32 |

| 305 -035 PW | 305 | 120 | 35 | 25 | 30 | 38 |

| 305 -040 PW | 305 | 120 | 40 | 30 | 35 | 45 |

| 280 -035 PW | 280 | 110 | 35 | 22 | 26 | 33 |

| 270 -040 PW | 270 | 106 | 40 | 27 | 31 | 40 |

| 255 -035 PW | 255 | 100 | 35 | 22 | 26 | 33 |

| 255 -040 PW | 255 | 100 | 40 | 25 | 29 | 37 |

| 230 -040 PW | 230 | 90 | 40 | 23 | 27 | 34 |

| 230 -045 PW | 230 | 90 | 45 | 30 | 35 | 45 |

| 225 -048 PW | 225 | 88 | 48 | 30 | 35 | 45 |

| 200 -045 PW | 200 | 79 | 45 | 25 | 29 | 38 |

| 200 -048 PW | 200 | 79 | 48 | 27 | 32 | 41 |

| 200 -055 PW | 200 | 79 | 55 | 26 | 30 | 39 |

| 180 -048 PW | 180 | 71 | 48 | 25 | 29 | 38 |

| 180 -055 PW | 180 | 71 | 55 | 26 | 30 | 39 |

| 160 -048 PW | 160 | 63 | 48 | 22 | 26 | 34 |

| 160 -063 PW | 160 | 63 | 63 | 26 | 30 | 39 |

| 150 -048 PW | 150 | 59 | 48 | 18 | 21 | 28 |

| 150 -048 PW | 150 | 59 | 48 | 19 | 22 | 29 |

| 150 -055 PW | 150 | 59 | 55 | 27 | 31 | 40 |

| 140 -063 PW | 140 | 63 | 63 | 24 | 28 | 37 |

| 135 -045 PW | 135 | 53 | 45 | 15 | 18 | 23 |

| 135 -048 PW | 135 | 53 | 48 | 18 | 20 | 26 |

| 135 -055 PW | 135 | 53 | 55 | 21 | 24 | 31 |

| 125 -071 PW | 125 | 49 | 71 | 25 | 29 | 38 |

| 120 -045 PW | 120 | 47 | 45 | 12 | 14 | 19 |

| 120 -048 PW | 120 | 47 | 48 | 17 | 20 | 25 |

| 120 -055 PW | 120 | 47 | 55 | 18 | 21 | 26 |

| 120 -063 PW | 120 | 47 | 63 | 26 | 31 | 40 |

| 110 -080 PW | 110 | 43 | 80 | 26 | 30 | 39 |

| 100 -055 PW | 100 | 39 | 55 | 17 | 20 | 26 |

| 100 -071 PW | 100 | 39 | 71 | 27 | 32 | 41 |

| 100 -071 PW | 100 | 27 | 71 | 22 | 25 | 33 |

| 90 -071 PW | 90 | 35 | 71 | 26 | 30 | 39 |

| 90 -080 PW | 90 | 35 | 80 | 27 | 31 | 40 |

| 80 -071 PW | 80 | 31 | 71 | 26 | 30 | 39 |

| 80 -100 PW | 80 | 31 | 100 | 27 | 32 | 41 |

| 60 -125 PW | 60 | 24 | 125 | 27 | 32 | 41 |

| 60 -150 PW | 60 | 24 | 150 | 30 | 35 | 45 |

Definition of Tension Classes

- Standard Tension

- Good for all printers using mechanical stretching devices or simpler printing machines that don’t include advanced controls that high tension screens would require.

- Advanced Tension

- Requires stable frames, an experienced technician, and a high quality stretching device. Operators will need to use minimum off-contact distance during printing.

- Expert Tension

- Suitable only for expert screen makers and machine operators utilizing state-of-the-art stretching equipment. Demands great care and minimum off-contact distance during printing.

Notes

- Recommended tension values are calculated from breaking tension measurements taken on a 100 cm x 100 cm (approx. 39.4″ x 39.4″) mechanical stretching device

Need More Information?

For assistance in achieving the ideal tension level for NBC mesh, please contact NBC Meshtec Americas at (800) 235-5056, or visit our team page to find the Technical Sales Representative for your area.